SPM Hawsers

|

|

Product Id: SPM Hawsers

Overview

Garware-Wall Ropes Ltd. is in the business of supplying hawsers for more than a decade. We have the necessary expertise and knowledge to manufacture all types of SPM hawsers.

We manufacture 8 strand ropes up to 15” circ. SPM ropes are manufactured from Nylon or Maxiflex (composite fiber rope of high strength Polypropylene & Polyester).

For the ropes above 15” Circ. in 8 strand plaited variety and for Double braided ropes of all sizes we import the ropes from internationally reputed rope manufacturers and do the assembly along with indigenous accessories.

We have been exporting hawsers to Europe and South East Asia.

All eminent Indian customer they trust on GWRL product & we supply 20 ~ 30 SPM hawsers in domestic market.

Our quality system is certified in accordance with ISO 9001: 2000 by BVQI, UK. Our Nylon and Maxiflex 8 Strand plaited ropes are manufactured as per OCIMF GUIDELINES and have undergone "PROTOTYPE ROPE TESTING" successfully in accordance with OCIMF guidelines.

INDIGENOUS SYSTEM

We produce and offer complete SPM systems in 8 Strand Plaited varieties with following specifications:

| Description |

NYLON |

MAXIFLEX |

| Type |

Single Leg |

Double Leg |

Single Leg |

Double Leg |

| Circ. |

14" Super |

14" Super |

15" |

15" |

B. Strength

(tones f ) |

277 |

470 |

286 |

485 |

The rope as well as accessories are manufactured and assembled in house as per OCIMF guidelines. Each process of rope making and assembling is inspected and certified by Lloyd's Register Asia.

ASSEMBLY

For ropes above 15" circ. in 8 Strand plaited variety ropes of any size, the Rope is imported from other suppliers.

Assembly and accessories are made in-house and the complete system with Lloyd's Certification is supplied.

Typical technical specification of Single / Double leg grommet assembly is enclosed. Also enclosed is the list of Past Supply details for reference.

The Salient features of our SPM Hawsers:

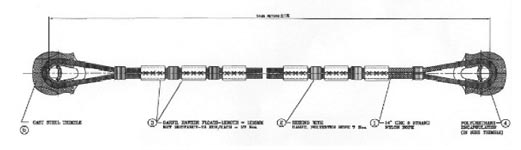

- The SPM hawser will be a Single / Double Leg Grommet type assembly made of Nylon / Maxiflex (up to 120 mm dia.) 8 strand Braided rope.

- PE braided netting with copper and steel wire to reduce algae growth and protection from predators

- The Length of the Hawser assembly will be maintained as required.

- The ropes will be manufactured, inspected and tested in accordance with OCIMF guidelines 2000 - First edition.

- The New Dry Breaking Strength of the rope would be verified by Third Party Surveyor i.e. Lloyd’s Register Asia.

- For double leg grommet assembly, the calculated assembly strength will be 1.7 times of the New Dry Breaking Strength of the rope.

- The TCLL (Thousand Cycle Load Level) value as determined by prototype cyclic load procedure described in OCIMF will be 75.63 % of NWBS (New Wet Breaking Strength) for Maxiflex ropes and 50 % for Nylon ropes.

- The material of the rope will be composite fiber i.e. Mix of Polyester and Polypropylene for Maxiflex and 100 % Nylon for Nylon ropes.

- For double leg systems the legs will be tied / seized together at minimum 7 places for a ength of 1.2 m each.

- For double leg grommet, each leg will have an end for end splice in the center thus balancing the total assembly.

- The rope will form soft eyes at each end. The ends will have a polyurethane encapsulated Cast Steel Thimble IS 1030 : 1998 Gr. 230 – 450 W grade

- The soft eyes of the ropes at the end can also be provided with reusable monel bollard K - 400 grade and Bell mouth thimbles IS 2062 grade

- The Thimbles and Monel blocks are ultrasonically tested. The Thimbles are Hot dip Galvanized to suit marine conditions.

- Rope legs inside the Bell Mouth Thimble will be covered with Polyurethane coated Polyester fabric for chafe protection.

- In case of Cast steel thimble, PU encapsulation shall be provided inside the thimble to prevent chafing.

- Additional optional protection such as PU cloth protection / Leather covering / Rubber sleeve can be provided as per customer’s desire

- Lace on type pocket hawser floats will be provided over the length of the Hawser at regular intervals so as to have at least 20 % reserve buoyancy to support the rope in sea.

- For double leg systems a double collar float will be provided over the Spliced portion of the rope

* Internationally recognized Factor for splice reduction in double leg grommet, supporting documents are enclosed.

INSPECTION

- Garware-Wall Ropes Ltd. will adhere to the quality assurance procedures which are prescribed in OCIMF guidelines - "Quality Control and Inspection during the Production of Hawsers".

- Third party inspection will be done according to the customer’s wish.

- Following are the tests carried out in the presence of third party Inspector in accordance with OCIMF guidelines.

- Verification of rope construction

- Verification of rope breaking strength.

- Verification of rope performance criteria as per prototype test results.

- Verification of auxiliary gear and 20% reserve buoyancy.

- Verification of thimble material and dimension as per customer approved drawing.

- Verification of chafe protections as per customer requirement.

- The inspection agency / third party will stamp the Thimbles of each rope after inspection.

Garfil MAXIFLEX:

These ropes are of composite fiber construction made from high tenacity polyester and polypropylene yarn in a specific composition.

Product Features

- Specific gravity is equivalent to Nylon.

- Higher strength compared to Nylon.

- No loss of breaking strength in wet conditions.

- A multifilament cover ensures excellent abrasion resistance.

- Retains flexibility even after prolonged use.

- Controlled elongation and high-energy absorption.

- Cost effective and less weight per meter as compared to Nylon.

- The ropes can also be supplied as per OCIMF guidelines.

PACKING

The hawsers will be packed in wooden boxes. The wooden boxes will be lined with PE film. Rope slings will be provided for lifting the box as well as the hawsers from the box. Total product description will be displayed at three sides of the box for customer reference.

- Mooring Lines

- Towing Lines

- On Board Oil Rigs

- SPM Hawsers

- Oil Exploration

Advantages of 8 strand constructions

- An 8 strand construction with 4 “s” way laid and 4 “z” way laid strands gives torque free and completely balanced mooring rope.

- 8 strand is a flexible construction under dry or wet condition. So easy to handle.

- Easy to inspect because of braided construction and so regular inspection on site is possible. In case of double braided internal structural damage in the core cannot be checked.

|

|

|

|