Overview

Ramset™ has traditionally held the major market share of the Masonry Anchor market within Australia. However, we have been heavily reliant on high

volume commodity products and have never addressed the High-Tec specification expansion anchor market with a Ramset™ branded product.

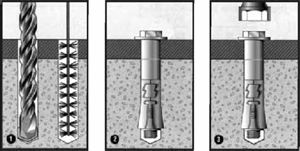

Heavy duty anchors are used in structural and critical applications as well as being recommended for use in tension zone applications. The reason they

are used in these applications relates to the ability of heavy duty anchors to further expand when loaded, should the concrete crack or existing cracks

widen under service load.

The total capacity for further expansion is achieved by the larger taper on the cone nut and expansion sleeve. Should the concrete crack, the cone nut

is drawn further into the expansion sleeve, thus further expanding the anchor and maintaining the load on the fixture.

The Ramset™ Spatec™ (Special Performance Anchor) is a high quality, predictable heavy duty anchor that is ideally suited to the fastening

of heavily loaded fixtures where security and reliability are primary considerations.

| Features |

Benefits |

| Rational design method |

Strength limit states data for specifier use |

| High static load capacity |

Through fixing eliminates marking out and repositioning fixtures |

| Torque controlled expansion |

Reliability guaranteed when set with torque wrench |

| High first slip load |

Suitable for cyclic load cases |

| Rotation inhibited when tightening bolt |

Ensures reliable torque/preload relationship |

| Integral anti rotation/pull down sleeve |

Reliable, all metal construction |

| High tensile 8.8 grade bolt |

Higher tensile and shear capacities available |

| Anti pull through sleeve design |

Anchor continues to resist load after being over loaded |

| Flush head bolt |

Low profile for aesthetic appeal |

| High shear load capacity |

All metal components of the Spatec anchor are passivated zinc coated with the addition of a gold chromate conversion coating |

Uses

- Lift guide rails

- Structural steelwork

- Gantry cranes

- Scaffolding

- Heavy machinery

- Pallet racking

- Heavy pipe support

- Building facades

- Construction props

Installation

The installer should be aware of the diameter and type of anchor required, its location and information on spacing and edge distance requirements.

Embedment depth, which is the total anchor length measured from the washer, less the sum of the fixture thickness and the total thickness of any

structural material, should be determined. Hole depth is found by adding half a nominal anchor diameter to embedment depth. Difficulty may be

experienced in inserting the anchor if the drill bit has worn smaller than the minimum.

If non-recommended drill bits (larger than the maximum) are used, the hole may be too large to develop the required friction force after

expansion of the anchor, leading to premature pull-through failure under applied load.

- Drill the hole to at least the embedment depth plus half anchor diameter. If drilling through the hole in the fixed material, drill to anchor length plus half anchor depth from the top of the fixture. A shallow hole may cause the bolt to bottom out and prevent the proper clamping of the fixed material. Clear all material from the hole. Blow out the dust.

- Check the anchor before replacement. There should be no gaps between components and the anti-rotation dog on the nylon pull-down should be engaged in the slot on top of the expansion sleeve. The cone nut should be finger tight in the bottom of the expansion sleeve, but the sleeve should not be expanded.

- Insert the anchor through the fixture and drive in until the washer just contacts the fixture. Over driving may damage the washer. The use of excessive force to drive in the anchor indicates either excessive cone entry or a worn drill bit.

- Tighten the bolt with the torque wrench to the appropriate friction sliding assembly torque. Using torque at static friction may lead to low pre-loads. Low assembly torque or pre-load may reduce the life of the fixing under cyclic loads. Excessive tightening may overstress the bolt.

|