Also available in zinc and Galvanised

Overview

Ramset™ released the Ankascrew™ onto the Australian market in February 2000.

Ankascrew™ was originally marketed to the Do It Yourself, home handyperson segment, but because of its simplistic design and ease of use, it has become a popular masonry anchor to all trades.

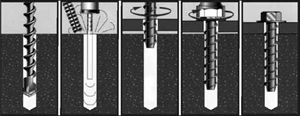

The Ankascrew™ is an innovative, self tapping screw-in anchor, used to fasten fixtures in the light to medium duty range and will fasten materials to concrete and

other solid masonry as well as hollow concrete block, solid pressed brick and extended wire cut bricks with holes therein.

The RamsetTM Ankascrew™ is a self tapping anchor with multi-use capabilities where the thread cuts into the substrate for a positive and secure anchorage.

| Features |

Benefits |

| Large 75 mm outer diameter thread |

For a positive cutting groove in substrate |

| Smaller integrated balancing thread |

Correct alignment in the hole |

| Bigger 25 degree helix angle thread pitch |

Greater tensile strength in all substrates |

| Single large cutting thread |

Less torque during installation |

| Reduced shank core diameter |

More tolerant to worn drill bits |

| Greater diameter between threads |

Deeper thread embedment,higher tensile loads |

| Single sharp cutting thread |

Greater contact grip over entire embedment |

| Smooth under head profile |

Reducing head failure when over torqued |

| No expansion forces |

Close to edge and centre to centre spacing’s |

| Greater diameter between threads |

Deeper thread embedment, higher tensile loads |

| Anchor diameter marked on head |

Same size masonry drill bit |

| Removable with ease |

Leaving a small neat hole to patch up |

Uses

- Pallet racking

- Temporary safety barriers

- Conveyors pipe brackets

- Gate hinges into brickwork

- Temporary hand rails

- Bottom plates

- Used for fast and simple anchoring into solid concrete and masonry or hollow brick and block

To achieve maximum loads the installation process needs to be carried out as follows:

Installation

- Drill a hole to the correct diameter and depth

- Clean hole with a brush and remove debris with vacuum or hand pump

- Using a socket wrench, screw the Ankascrew™ into the hole exerting a slight downward pressure until the “self-tapping” starts

- Tighten the Ankascrew™. If resistance is experienced whilst tightening, unscrew fastener one turn and re-tighten, ensuring not to overtighten

NOTE: Hole depth = bolt length fixture thickness + overdrill depth.

|